Technology

Liquid Silicone Injection Molding: Everything You Need to Know

Published

7 months agoon

By

IQnewswire

Liquid Silicone Injection Molding (LIM) is transforming the way industries manufacture precision silicone parts. From medical devices to automotive seals, this innovative process offers unmatched versatility, durability, and efficiency. In this guide, we’ll explore what LIM is, its benefits, applications, and why it’s the go-to choice for many industries.

What Is Liquid Silicone Injection Molding?

Liquid Silicone Injection Molding is a manufacturing process that involves injecting liquid silicone rubber (LSR) into a mold cavity. Once injected, the silicone is cured at high temperatures to produce a durable, flexible, and heat-resistant component.

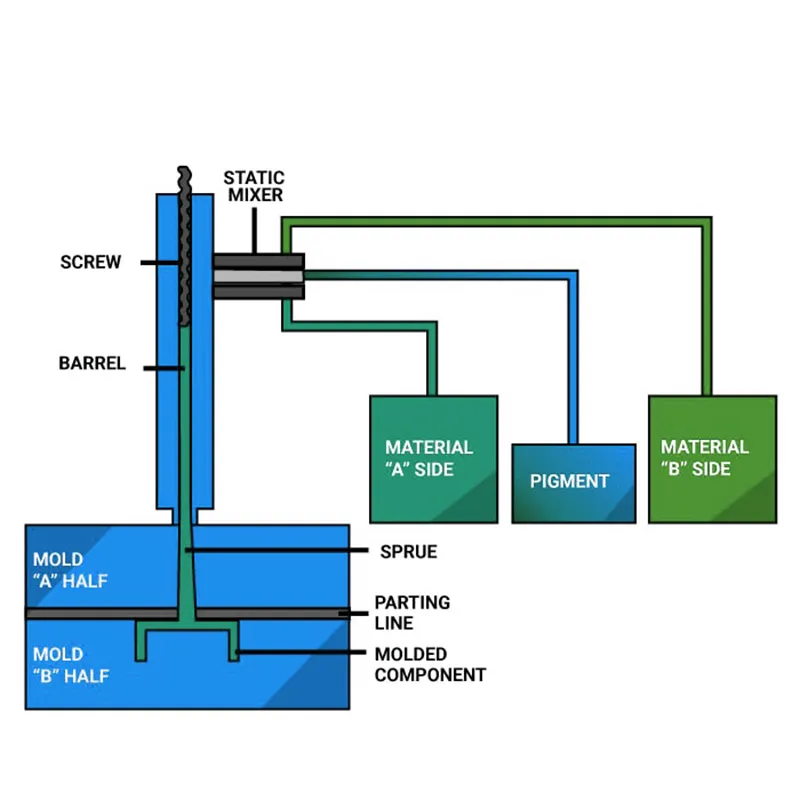

How the LIM Process Works

The LIM process involves several key steps:

- Mixing: Two liquid silicone components (A & B) are mixed in a precise 1:1 ratio.

- Injection: The mixture is injected into a heated mold under high pressure.

- Curing: The silicone is vulcanized (cured) inside the mold, solidifying it.

- Ejection: Once cured, the part is ejected and ready for finishing or assembly.

This method is highly automated, making it ideal for producing high volumes of parts with consistent quality.

Key Benefits of Liquid Silicone Injection Molding

1. High Precision and Repeatability

LIM offers exceptional dimensional accuracy, making it perfect for tight tolerance parts.

2. Excellent Material Properties

Liquid silicone rubber is heat-resistant, chemically stable, biocompatible, and extremely flexible—even in extreme temperatures.

3. Fast Cycle Times

Because LIM is an automated process, it offers rapid cycle times, increasing production efficiency.

4. Minimal Waste

Closed-loop systems and precision injection minimize material waste, contributing to cost efficiency and sustainability.

Applications of Liquid Silicone Injection Molding

LIM is used across various industries, including:

Medical and Healthcare

- Catheters

- Respirator masks

- Seals and gaskets

- Baby bottle nipples

Automotive Industry

- Grommets and seals

- Connectors and housings

- High-performance engine components

Consumer Products

- Wearable tech

- Kitchen utensils

- Baby care products

Electronics

- Keypads

- Encapsulated components

- Waterproof seals

Tooling for Silicone Injection Molding

Precision Mold Design

LIM requires specially designed molds made from hardened steel or aluminum, depending on the production volume.

Cold Runners vs. Hot Runners

- Cold runners help reduce material waste by reusing uncured LSR.

- Hot runners are less common in LIM but used in specialized setups.

Proper mold design ensures part integrity, cycle efficiency, and repeatability.

Challenges in Liquid Silicone Injection Molding

While LIM offers many advantages, it does come with challenges:

1. Initial Tooling Cost

Custom molds can be expensive to produce, especially for complex parts.

2. Material Handling

LSR must be handled and stored correctly to avoid contamination or premature curing.

3. Design Constraints

Certain design limitations exist due to the flow characteristics of liquid silicone.

However, with proper planning and expertise, these challenges can be effectively managed.

Best Practices for Silicone Injection Molding Design

To ensure the success of your LIM project, consider the following:

- Uniform wall thickness to prevent voids or air traps

- Draft angles for easier part ejection

- Avoid sharp corners to reduce stress concentrations

- Use venting and gating correctly to ensure complete mold filling

Working with an experienced silicone injection molding partner can make a big difference in part performance and manufacturing efficiency.

Environmental Impact and Sustainability

Liquid silicone rubber is inherently more sustainable than many petroleum-based plastics. Its durability means longer product life, reducing the need for replacements. Moreover:

- LIM processes generate minimal waste

- Many LSR grades are recyclable

- LSR is non-toxic and hypoallergenic

As manufacturers move toward greener practices, LIM fits perfectly into eco-conscious production lines.

Choosing the Right Silicone Injection Molding Partner

When selecting a manufacturing partner for your LIM needs, evaluate:

- Experience with LSR and mold design

- Production capabilities (volume, tolerances, cleanroom facilities)

- Certifications (ISO 13485 for medical, IATF 16949 for automotive)

- Material sourcing (medical-grade, FDA-compliant, UL-rated)

A knowledgeable partner can assist with everything from prototype to mass production.

Future of Liquid Silicone Injection Molding

The LIM industry continues to grow with advancements in:

- Micro-molding for tiny medical and electronic parts

- Overmolding with LSR on plastic or metal substrates

- Smart materials like conductive silicone

- Sustainable LSR made from renewable resources

These innovations ensure that LIM remains a cornerstone of precision manufacturing.

Conclusion

Liquid Silicone Injection Molding is a game-changing process that enables the production of high-performance silicone components with superior accuracy, speed, and quality. Its wide range of applications across industries like medical, automotive, and consumer products proves its versatility. Whether you’re launching a new product or scaling an existing one, LIM offers a cost-effective, reliable, and eco-friendly solution.

Can the Fed Stop Inflation Without Breaking the Economy?

Accounting and Payroll Software for UK Small Businesses: A Practical Guide

Vietnam’s Rising Position on the Global Technology Map

The Ultimate Guide to Expert Car Detailing with Jim’s Car Detailing

Why Effective Data Management is Key to Business Success

2026 Guide to Renting in Worthing: Is It Affordable & Livable Compared to the South East?

Top Tips to Find the Best Fridges for Sale at Sydney Wide Discounts

Why Hiring a Property Lawyer in Sydney is Essential for Your Real Estate Success

AI Consulting: A Suitable Guide to Transform Your Business in the UK

What’s Changed in the Way People Plan Later in Life

Revolutionizing Healthcare: The Emergence of AI-Driven Analytics

Carol Kirkwood’s Journey: Her Real Age, Husband, Career, and More

How Machine Learning and AI are Redefining the Future?

Aliza Barber: Meet Lance Barber’s Wife, Age, Life, Profile, Career and Net Worth

Evelyn Melendez: Jordan Knight’s Wife Bio, Marriage, Family, Career and Net Worth

Body Positivity and Bodycon: Embrace Your Shape with Homecoming Dresses

Ilan Tobianah Biography: Family, Marriage, Lifestyle, Career and Net Worth

King Von’s Autopsy Report: The Truth Behind the Tragic Death

Who was Alice Marrow? Everything to Know About Ice-T’s and His Mother

Meet Otelia Cox: The Supportive Wife of Tony Cox – A True Fairy Tale Romance

Can the Fed Stop Inflation Without Breaking the Economy?

Accounting and Payroll Software for UK Small Businesses: A Practical Guide

Vietnam’s Rising Position on the Global Technology Map

The Ultimate Guide to Expert Car Detailing with Jim’s Car Detailing

Why Effective Data Management is Key to Business Success

2026 Guide to Renting in Worthing: Is It Affordable & Livable Compared to the South East?

Top Tips to Find the Best Fridges for Sale at Sydney Wide Discounts

Why Hiring a Property Lawyer in Sydney is Essential for Your Real Estate Success

AI Consulting: A Suitable Guide to Transform Your Business in the UK

What’s Changed in the Way People Plan Later in Life

Category

Trending

-

Health2 years ago

Health2 years agoRevolutionizing Healthcare: The Emergence of AI-Driven Analytics

-

News6 months ago

News6 months agoCarol Kirkwood’s Journey: Her Real Age, Husband, Career, and More

-

Technology2 years ago

Technology2 years agoHow Machine Learning and AI are Redefining the Future?

-

Celebrity2 years ago

Celebrity2 years agoAliza Barber: Meet Lance Barber’s Wife, Age, Life, Profile, Career and Net Worth