Technology

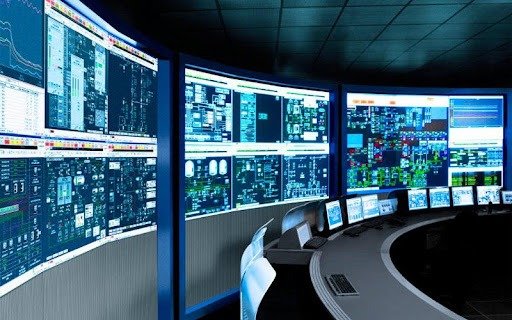

SCADA-Integrated HMI Solutions – Unified Control & Real-Time Visualization

Published

2 weeks agoon

By

Prime Star

Industrial automation has transformed manufacturing, energy, and infrastructure management across every sector. At the heart of these modern systems lies SCADA (Supervisory Control and Data Acquisition) technology, paired with sophisticated Human Machine Interface (HMI) solutions that enable operators to monitor, control, and optimize complex processes with unprecedented precision.

SCADA & System Integration HMI Solutions represent the convergence of hardware, software, and networking technologies that allow organizations to centralize control over distributed systems. Whether you’re managing a water treatment facility, coordinating manufacturing processes, or overseeing power distribution networks, these integrated solutions provide the visibility and control necessary for efficient operations.

This comprehensive guide explores how SCADA systems work, the critical role of HMI interfaces, and the benefits of integrated solutions for modern industrial applications. You’ll discover key features to look for, implementation considerations, and how these technologies can enhance your operational efficiency while reducing costs and improving safety outcomes.

Understanding SCADA Systems and Their Core Functions

SCADA systems serve as the central nervous system for industrial operations, collecting data from remote locations and providing operators with real-time visibility into system performance. These systems excel at monitoring geographically dispersed assets, from oil pipelines spanning hundreds of miles to manufacturing plants with multiple production lines.

The architecture of SCADA systems typically includes several key components working together seamlessly. Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs) collect data from field devices such as sensors, meters, and actuators. This information travels through communication networks to a central SCADA server, where specialized software processes and stores the data for operator access.

Modern SCADA implementations go beyond basic monitoring and control. They incorporate advanced analytics capabilities, allowing organizations to identify trends, predict maintenance needs, and optimize processes based on historical data patterns. This evolution has made SCADA systems indispensable for maintaining competitive advantage in industrial environments.

Data visualization represents another crucial function of contemporary SCADA systems. Operators need intuitive ways to understand complex system states quickly, especially during emergency situations. Effective SCADA solutions present information through customizable dashboards, trending graphs, and alarm management systems that prioritize critical events while filtering out routine notifications.

The Essential Role of HMI in Industrial Operations

Human Machine Interface technology bridges the gap between complex industrial systems and the operators who manage them. HMI solutions transform raw data streams into meaningful, actionable information that enables quick decision-making and efficient system control.

Effective HMI design prioritizes user experience without sacrificing functionality. The best interfaces present critical information prominently while allowing operators to drill down into detailed system data when needed. This hierarchical approach to information display helps prevent cognitive overload during normal operations while ensuring comprehensive data access during troubleshooting scenarios.

Touchscreen capabilities have revolutionized HMI interaction, making systems more intuitive and reducing training requirements for new operators. Modern HMI devices support multi-touch gestures, allowing operators to zoom, pan, and navigate through system displays with familiar smartphone-like interactions. This evolution has significantly improved operator efficiency and reduced the learning curve for new technologies.

Security considerations have become paramount in HMI design as industrial systems face increasing cybersecurity threats. Advanced HMI solutions incorporate user authentication, role-based access controls, and encrypted communications to protect against unauthorized access. These security measures ensure that only qualified personnel can make critical system changes while maintaining detailed audit trails for compliance purposes.

Key Benefits of Integrated SCADA HMI Solutions

Integration between SCADA systems and HMI interfaces creates synergies that exceed the sum of their individual capabilities. Unified platforms eliminate data silos, reduce configuration complexity, and provide consistent user experiences across different operational areas.

Cost efficiency emerges as a primary advantage of integrated solutions. Organizations can reduce licensing fees, simplify maintenance contracts, and streamline training programs when using cohesive technology platforms. Single-vendor solutions often provide better technical support experiences, as troubleshooting doesn’t require coordination between multiple software providers.

Scalability becomes significantly easier with integrated platforms. As organizations grow or modify their operations, integrated SCADA HMI solutions can accommodate new devices, additional users, and expanded functionality without requiring complete system overhauls. This flexibility protects technology investments while supporting business evolution.

Real-time performance optimization represents another key benefit of integration. When SCADA data collection and HMI presentation operate on the same platform, information updates occur faster and more reliably. This improved responsiveness enables operators to react quickly to changing conditions, potentially preventing costly downtime or safety incidents.

Essential Features for Modern SCADA HMI Solutions

Comprehensive alarm management capabilities distinguish professional-grade SCADA HMI solutions from basic monitoring systems. Effective alarm systems provide intelligent filtering, priority-based notification, and escalation procedures that ensure critical events receive appropriate attention without overwhelming operators with routine status updates.

Historical data storage and trending functionality enable organizations to analyze long-term patterns and optimize processes based on empirical evidence. Modern solutions provide flexible data retention policies, allowing organizations to balance storage costs with analytical requirements while maintaining compliance with industry regulations.

Remote access capabilities have become essential for modern industrial operations. SCADA & System Integration HMI Solutions should support secure remote monitoring and control, enabling expert technicians to assist with troubleshooting from off-site locations. This capability reduces response times for critical issues while expanding access to specialized expertise.

Multi-platform compatibility ensures that SCADA HMI solutions can integrate with existing infrastructure investments. The best solutions support connections to diverse device types, communication protocols, and third-party software systems. This flexibility prevents vendor lock-in while maximizing the value of current technology assets.

Implementation Strategies for Maximum Success

Successful SCADA HMI implementation begins with thorough requirements analysis. Organizations must clearly define their monitoring objectives, identify critical control points, and establish performance metrics before selecting specific technologies. This upfront planning prevents scope creep and ensures that implemented solutions address actual operational needs.

Phased deployment approaches reduce implementation risk while providing opportunities to refine system configurations based on real-world experience. Starting with pilot installations allows organizations to validate technology choices, train personnel, and develop standard operating procedures before full-scale deployment.

Training programs deserve significant attention during SCADA HMI implementation. Even the most sophisticated systems provide limited value if operators lack the knowledge to use them effectively. Comprehensive training should cover both normal operations and emergency response procedures, ensuring that personnel can maintain system effectiveness under various conditions.

Change management processes become critical when introducing new SCADA HMI technologies. Organizations should establish clear procedures for system modifications, ensuring that changes undergo appropriate testing and approval before implementation. This discipline prevents unauthorized modifications that could compromise system reliability or security.

Future-Ready SCADA & System Integration HMI Solutions

Modern industrial environments demand SCADA & System Integration HMI Solutions that can adapt to evolving operational requirements while maintaining reliable performance. The convergence of operational technology with information technology creates new opportunities for efficiency improvements, but also introduces additional complexity that requires sophisticated management tools.

Cloud integration capabilities are transforming how organizations approach SCADA HMI deployment and management. Hybrid architectures that combine on-premises control systems with cloud-based analytics and reporting provide enhanced scalability while maintaining local control authority. These approaches enable organizations to leverage advanced analytics capabilities without compromising operational security.

Artificial intelligence and machine learning integration represent the next frontier for SCADA HMI evolution. These technologies can identify subtle patterns in operational data that human operators might miss, potentially predicting equipment failures before they occur or identifying optimization opportunities that improve efficiency without requiring capital investment.

Investing in comprehensive SCADA & System Integration HMI Solutions positions organizations for sustained competitive advantage in increasingly complex industrial environments. The key lies in selecting solutions that balance current operational needs with future expansion capabilities, ensuring that technology investments continue providing value as business requirements evolve.

You may like

Compare and Choose Your Online Help to Succeed in Your Online Classes

ck2generatorcom: The Coolest Way to Build Your Own Crusader Kings II World

noneofyourissueshoe: The Shoe That Solves All Your Foot Problems

Stress-Free Consultations for Dental Implants Newcastle Patients

Dental Implants Newcastle for Better Chewing and Comfort

The ROI of Hiring a Digital Marketing Agency: Is It Worth It?

Understanding Carpet Cleaning Prices: What Affects the Cost of Services?

Changes in Facial Puffiness and Hollowing Throughout the Day

Why Acrylic Stands Are Ideal for Museum Displays

AaryaEditz org: The Smart Way to Edit Photos and Videos Online

Revolutionizing Healthcare: The Emergence of AI-Driven Analytics

How Machine Learning and AI are Redefining the Future?

Aliza Barber: Meet Lance Barber’s Wife, Age, Life, Profile, Career and Net Worth

Evelyn Melendez: Jordan Knight’s Wife Bio, Marriage, Family, Career and Net Worth

Who was Alice Marrow? Everything to Know About Ice-T’s and His Mother

Ilan Tobianah Biography: Family, Marriage, Lifestyle, Career and Net Worth

Meet Otelia Cox: The Supportive Wife of Tony Cox – A True Fairy Tale Romance

King Von’s Autopsy Report: The Truth Behind the Tragic Death

Tex9.net Business: Solve Business Problems with the Help of Tex9.net

Exploring Real Estate Market: Smart Strategies for Savvy Investors

Compare and Choose Your Online Help to Succeed in Your Online Classes

ck2generatorcom: The Coolest Way to Build Your Own Crusader Kings II World

noneofyourissueshoe: The Shoe That Solves All Your Foot Problems

Stress-Free Consultations for Dental Implants Newcastle Patients

Dental Implants Newcastle for Better Chewing and Comfort

The ROI of Hiring a Digital Marketing Agency: Is It Worth It?

Understanding Carpet Cleaning Prices: What Affects the Cost of Services?

Changes in Facial Puffiness and Hollowing Throughout the Day

Why Acrylic Stands Are Ideal for Museum Displays

AaryaEditz org: The Smart Way to Edit Photos and Videos Online

Category

Trending

-

Health2 years ago

Health2 years agoRevolutionizing Healthcare: The Emergence of AI-Driven Analytics

-

Technology2 years ago

Technology2 years agoHow Machine Learning and AI are Redefining the Future?

-

Celebrity1 year ago

Celebrity1 year agoAliza Barber: Meet Lance Barber’s Wife, Age, Life, Profile, Career and Net Worth

-

Celebrity1 year ago

Celebrity1 year agoEvelyn Melendez: Jordan Knight’s Wife Bio, Marriage, Family, Career and Net Worth